|

1234 Washington Street

|

|

|

|

1234 Washington Street

|

|

|

|

|

|

|

|

|

|

|

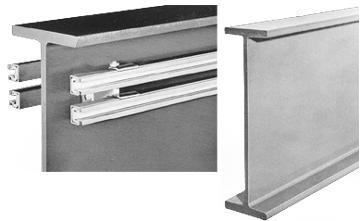

RailmasterTM TrackA dense uniform fine textured steel track of high tensile strength, with a profile incorporating a flat tread allowing accurate bearing of trolley wheels for efficient operation. The heavy flanges offer high resistance to wear and peining down under applied rolling loads. |

|

|

|

|

|

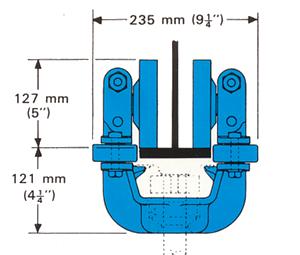

RailmasterTM Trolleys |

|

| These heavy duty trolleys are designed specially for use on RailmasterTM

and Expanded RailmasterTM runway systems.

They are available as two, or with a special alloy steel load bar, four wheeled

units capable of handling 5000 - 10,000 lb (2,268 - 4,536 kg). Eight-wheeled

hoist block adaptations are also available in capacities up to 17,000 lb (7711

kg). The trolleys are equipped with drop forged flangeless wheels which have hardened machine treads and are equipped with heavy duty, double row precision ball bearings. The machined steel axles are accommodated in a heavy malleable yoke casting and lubrication is provided through the axle by a Tecalemit fitting. To reduce track scuffing all trolleys are of the articulating type, being seated on a thrust-race combined with a spherical washer. Double-row ball bearing lateral guide rollers are also fitted to keep the trolleys in perfect alignment under high speed travel. |

|

|

|

|

|

|