KANT-SHOCKTMSafety type shielded electrification for crane and monorail systems.

Main Features:

- Complete protection against accidental contact

- Complies with I.E.C. Finger Test Safety Standards

- Trouble free operation, minimal maintenance

- Economical installation and operation

- Ideal for both indoor and outdoor applications

- Proven reliability

- Two capacities available with 80 amp range designed for curves, switches,crossover tracks and discontinuous control circuits.

|

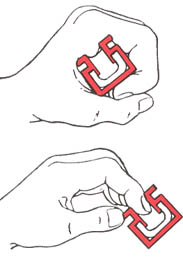

| Isometric view of Kant-Shock showing how the PVC completely encloses the conductor bar except for the narrow slot provided for the conductor shoe. |

|

Top: Cannot make contact

Bottom: Finger will not enter |

|

|

End Caps

To protect the ends of Kant-Shock Electrification from possible contact, heavy neoprene caps are snapped securely over the shielding at each end of the system. End stops on monorail track should be located so that the collectors do not hit the caps. |

|

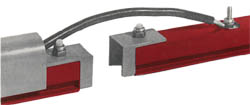

| Expansion Joint

Used at building expansion joints and at 300 ft. intervals of each conductor run for normal installations. The expansion joint allows for expansion and contraction, keeps the separated conductor bars in alignment, and guides the collector shoe across the gap. A length of high tension insulated cable attached to the end of each conductor bar forming the expansion joint, bridges the gap electrically. The cable is connected to the standard feed in clamp screws and fully shrouded by a polyvinyl snap on cover. Should a gap be installed at the centre of a run, power-feeds may be attached directly to these bridging wires. Maximum permissible gap at any one joint is 1". Should more expansion than this be desirable in the scheme further joints must be installed in the system. |

Insulating Section

For automatic dispatch control or other locations where conductor bars must be isolated, an insulating section of dielectric material is furnished to fit securely inside the Kant-Shock Shielding and match the adjoining conductor bars. These insulating sections can be located at any desired point in the system. |

|

|

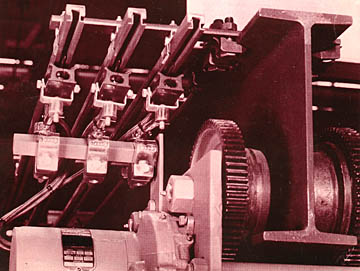

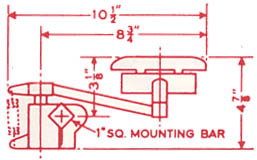

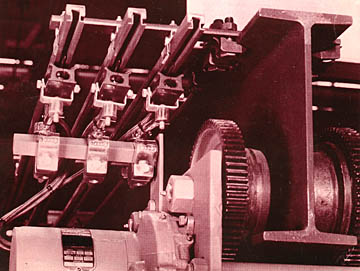

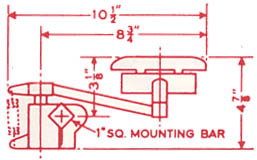

Collectors have a self cleaning sliding shoe collector, set in a moulded plastic insulator, which fits on an articulated trolley arm. The trolley arm is spring loaded to keep the collector in correct alignment with the conductor at all times. |

|

Power Feeds

Power can be fed to Kant-Shock Electrification at any point, preferably at a splice. The feed wire is secured to the back of the Splice Clip by simply placing the cable tag under one of the splice nuts. A Kant-Shock splice cover with one end plug removed is then snapped on to provide complete insulation.

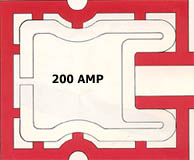

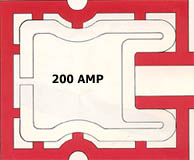

The higher rated requirements are adequately covered by the 200 amp range of the Kant-Shock shielded electrification system. The system is mechanically stronger and more rigid than others of similar electrical capacity utilizing copper or similar materials for the conductor.

|

|

Festoon Systems for Flatform & Round Cables |

Advantages:

-

Elimination of mobile collectors which prevents sparks, small electrical arcs, loss of energy and dropping of tension when the current passes from one element to another, trolleys, etc.

-

Perfect insulation

-

Easy, rapid mounting, maintenance free

|

|