|

1234 Washington Street

|

|

|

|

1234 Washington Street

|

|

|

|

|

|

|

|

|

|

|

2 Ton Capacity Systems |

|

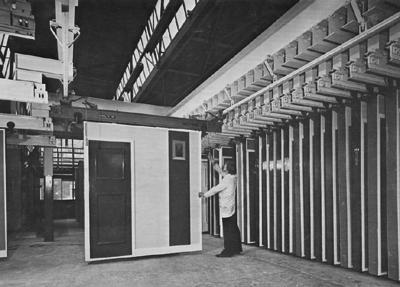

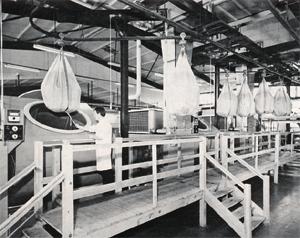

| United States Monorail overhead handling systems can be differentiated into a number of parts, each having an individual role. A large system may have a dozen interlocking bridge cranes, two jib cranes, fifty trolleys and hoists, two dip sections, monotractors (power driven trolleys), and a few thousand feet of track. This system could well have grown over a number of years - every year extending to a different department. | |

|

|

|

|

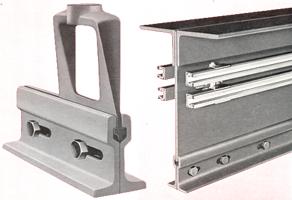

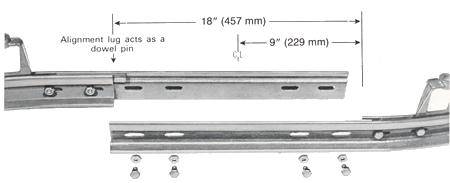

Splicing MethodNo Joint Clamps ensure smooth trolley travel. An overlapping splice is staggered to form a continuous track over which trolley wheels travel easily. |

|

|

|

|

|

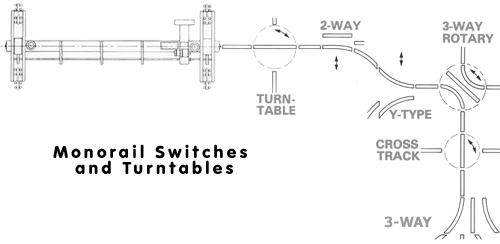

Monorail Switches and TurntablesComplete Range of Switches for omni-directional movement. Compact design allows closest spacing possible of branch tracks with maximum overhead space. Glide type switches provide positive alignment for load transfer over straight or curved tracks. Manual switches operate from pendant cord controls with pneumatic or electric remote control available. |

|

|

|

|

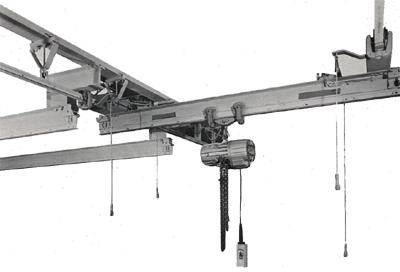

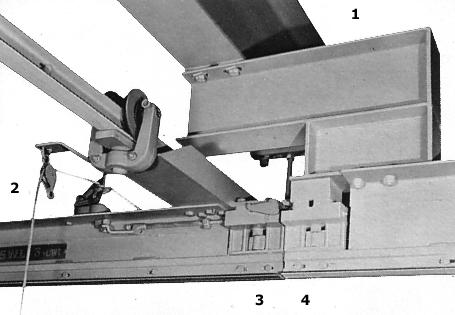

Monorail Crane and Interlock SystemThe crane system incorporates similar articulating trolleys for the crane end trucks and hoist trolleys as used on the Monorail system. The fabricated Girder Rail section is included for the crane bridge and the cranes operate on either basic Monorail or the Girder runways. The maximum crane span when operating on two tracks is 30 ft. (9 meters) and the crane range is up to 4000 lbs. (1800 kgs.). The cranes can be of the push-pull type or alternatively power operated. U.S. Monorail Crane Interlocks operate with extreme ease and safety. The latch bolt in the crane interlock, when set for operation by rope pull, is held in place by a keeper gate. This gate, upon reaching the con11t::LA111Y interlock is raised by a cam on the connecting interlock, releasing the bolt into the connecting interlock. By means of a rotating head in the connecting interlock, this latch bolt motion projects a second latch bolt from the connecting interlock into the crane interlock, thereby opening the safety stops for passage of trolley wheels across the connection. From this it can be seen that it is impossible to release the safety stops unless the crane is locked in alignment with the connecting interlock. |

|

|

|

|

|

|

|

|

|

System IntegrationEliminate Double Handling - With standard components systems are integrated with ease. This is achieved by an interlocking or latching system which enables loads to be transferred between bridges and spur tracks. |

|

|

|

|

|

|

|

|